Products

The Rotary Grinding Machine is a highly specialized tool designed for precision surface finishing in the manufacturing industry. Engineered for optimal performance, it features a high-speed rotating grinding wheel to remove material from workpieces, ensuring smooth, uniform finishes. This machine is particularly suited for applications that demand fine surface quality, such as automotive parts, aerospace components, electronics, and medical devices. The Rotary Grinding Machine is capable of handling a wide range of materials, including metals, ceramics, and composites, ensuring its versatility across various manufacturing sectors. It delivers consistent, high-quality finishes even under continuous operation, reducing variability and enhancing productivity. The machine’s precision is ideal for industries where tight tolerances and high consistency are critical.

Cash,Cheque,Demand Draft,UPI, NEFT

Key Attributes

- Grinding Wheel Diameter 400 mm

- Maximum Workpiece Weight 200 kg

- Power Consumption 7.5 kW

- Spindle Speed 1500 rpm

- Table Size 500 mm x 500 mm

- Machine Dimensions (L x W x H) 2000 mm x 1500 mm x 1800 mm

- Grinding Wheel Speed 3000 rpm

- Maximum Material Removal Rate 0.5 mm/min

- Number of Axes 3

- Minimum Surface Finish 0.2 microns

The Okamoto Double Column Grinding Machine is a cutting-edge piece of equipment designed for high-precision surface grinding in industrial applications. With a robust double column construction, this machine ensures exceptional stability and rigidity, enabling smooth and accurate grinding of even the most demanding workpieces. Its advanced design and technology allow for consistent surface finishes with minimal vibration, ensuring the highest level of precision for manufacturers in industries such as automotive, aerospace, mold and die production, and general metalworking. Equipped with powerful motors and advanced speed control features, the Okamoto Double Column Grinding Machine operates efficiently, reducing downtime and maximizing throughput. Its user-friendly interface provides operators with easy control over grinding parameters, ensuring a seamless user experience.

Cash,Cheque,Demand Draft,UPI, NEFT

Key Attributes

- Grinding Capacity 800mm

- Table Size 1600mm

- Motor Power 15 kW

- Wheel Size 400mm

- Maximum Load 1500 kg

- Travel (X-axis) 1200 mm

- Travel (Y-axis) 800 mm

- Travel (Z-axis) 600 mm

- Speed Range 100–1500 RPM

- Accuracy 0.001 mm

The Okamoto PSG 52AN Precision Surface Grinding Machine is designed for high-precision surface finishing in various manufacturing sectors. This machine offers a maximum grinding capacity of 500 x 200 mm, enabling the processing of larger workpieces with ease. Its grinding wheel size, measuring 350 x 50 x 127 mm, ensures efficient material removal and smooth surface finishes. The machine's table travel allows for up to 600 mm in the longitudinal direction and 200 mm in the cross direction, providing flexibility in handling different part sizes. The distance between the table and the grinding wheel is 450 mm, offering ample space for larger components. Powered by a 5 HP motor, the PSG 52AN delivers robust performance, driving the grinding process with precision. The machine supports variable feed rates, with speeds ranging from 10 to 1000 mm/min in the longitudinal direction and 10 to 500 mm/min in the cross direction, allowing for fine control over the grinding process. The spindle speed range of 1440 RPM enables the machine to perform at high rotational speeds, contributing to fast and accurate grinding.

Cash,Cheque,Demand Draft,UPI, NEFT

Key Attributes

- Grinding Capacity (Max. Work Size) 500 x 200 mm

- Grinding Wheel Size 350 x 50 x 127 mm

- Table Travel (Longitudinal) 600 mm

- Table Travel (Cross) 200 mm

- Max Distance from Table to Wheel 450 mm

- Power of Grinding Motor 5 HP

- Feed Rate (Longitudinal) 10-1000 mm/min

- Feed Rate (Cross) 10-500 mm/min

- Spindle Speed Range 1440 RPM

- Machine Weight 2,500 kg

The machine is designed for ease of operation, featuring user-friendly controls that allow quick adjustments, making it highly adaptable to different types of workpieces. The compact design of the machine maximizes space efficiency, while its heavy-duty construction ensures durability and reliability in demanding production environments. Whether used in high-volume manufacturing or specialized small-batch work, the Okamoto Rotary Surface Grinding Machine is engineered to deliver outstanding results every time. This machine is not only perfect for metalworking but also excels in other areas like surface preparation for welding and coating, grinding bearing surfaces, and manufacturing parts for the power generation and electronics industries. Its versatility and precision make it a trusted choice for businesses looking to enhance their production capabilities while maintaining the highest standards of quality.

Cash,Cheque,Demand Draft,UPI, NEFT

Key Attributes

- Grinding Capacity (mm) 520 x 200

- Maximum Grinding Length (mm) 520

- Maximum Workpiece Height (mm) 200

- Spindle Speed (RPM) 1450

- Motor Power (kW) 5.5

- Table Speed (m/min) 4

- Workpiece Weight (kg) 350

- Wheel Size (mm) 200 x 25 x 50

- Weight (kg) 1500

- Overall Dimensions (mm) 2,200 x 1,400

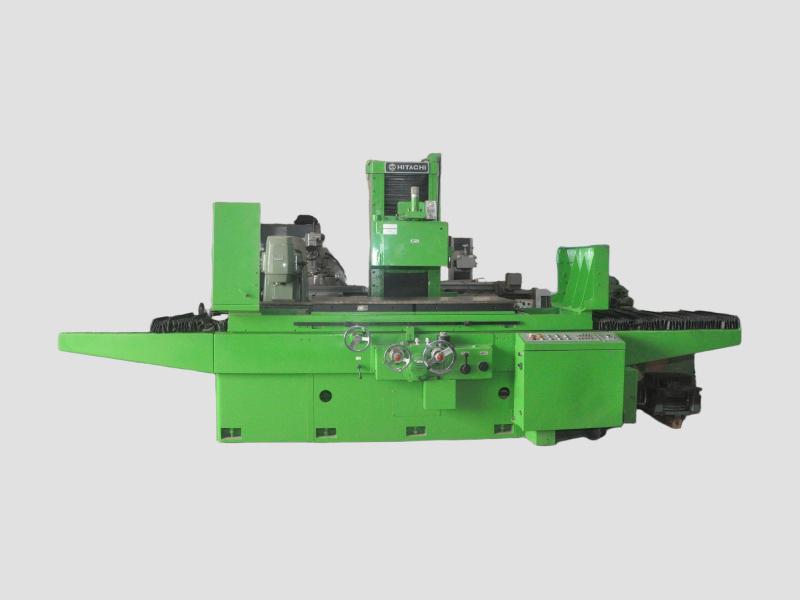

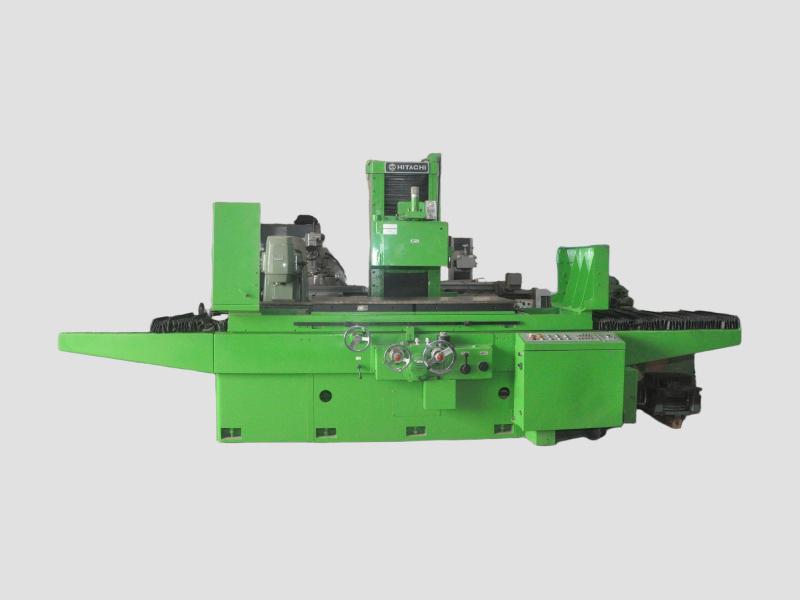

The Hitachi Surface Grinding Machine is designed for precision manufacturing in the metalworking industry. It features a high-performance motor, large grinding wheel, and a robust table that ensures efficient grinding of metal surfaces. With a motor power of 7.5 kW and a spindle speed of 1500 rpm, it guarantees consistent and high-quality finishes. The machine's capabilities include a grinding depth precision of 0.01 mm, making it ideal for industries like aerospace, automotive, and electronics. Additionally, its hydraulic pressure system supports smooth operation, while its ability to handle large workpieces (up to 1000 kg) makes it suitable for demanding applications. Perfect for industries requiring fine surface finishes, this machine ensures precise, reliable results.

Cash,Cheque,Demand Draft,UPI, NEFT

Key Attributes

- Grinding Wheel Size 500 mm

- Motor Power 7.5 kW

- Table Size 1000 x 500 mm

- Maximum Grinding Depth 0.01 mm

- Spindle Speed 1500 rpm

- Machine Weight 2500 kg

- Maximum Workpiece Weight 1000 kg

- Hydraulic Pressure 10 MPa

- Overall Dimensions (L x W x H) 2500 x 1500 x 1800 mm

- Power Supply 380 V